Mixing and process tanks –

individual, compact, safe

Do you need stainless steel mixing and process tanks for your application that are individually built according to your wishes, make work processes easy and at the same time offer 100% occupational safety?

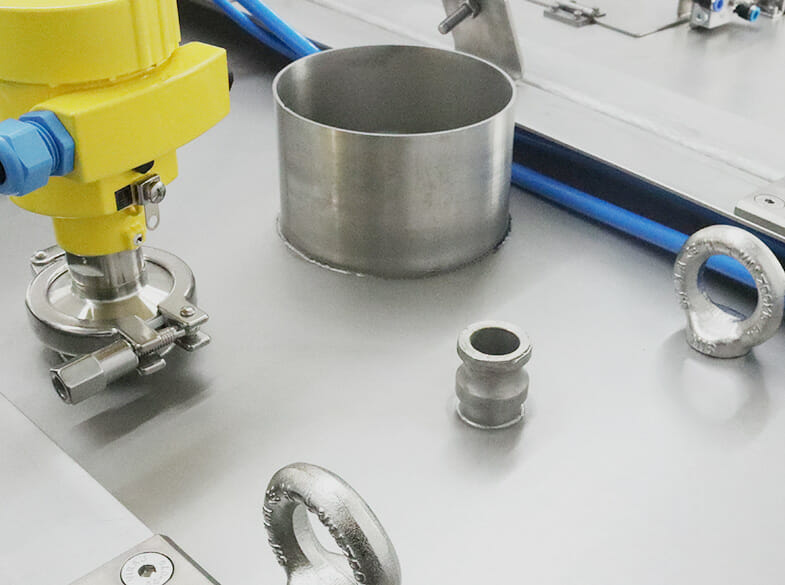

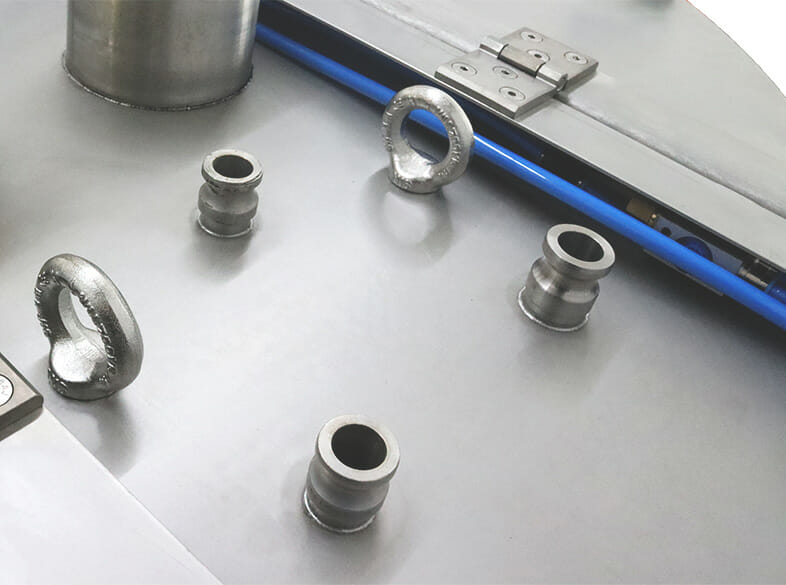

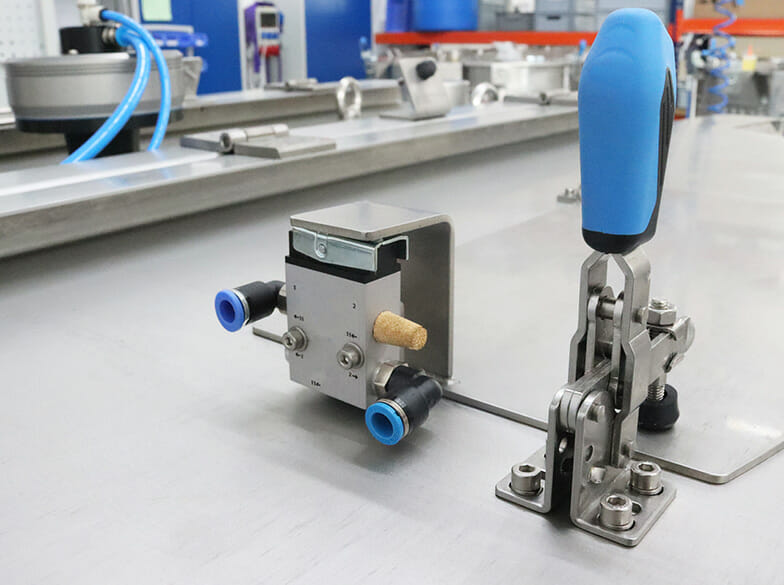

Together with you, we plan the dimensions, special features and equipment of your stainless steel tanks. We present you with an existing range of standardized accessories to choose from. We construct additional, more specific equipment in our development individually according to your technical requirements.

Depending on the mixing task, we select a pneumatic, a stainless steel or an electric drive from our range as the drive for the agitator. You can get an initial overview of our drives here.

This is how you get your perfect solution and the optimal price-performance ratio. With our detailed cost estimates, you always have an overview of your project.

Rely on our many years of experience in the areas of food, pharmaceuticals, cosmetics and clean rooms: hygiene, pharmaceutical and food conformity, ATEX or occupational safety are topics of our daily work. We realistically assess feasibility and optimization options.

At the end of the project, our technicians will also be happy to install your finished system at your site and take care of regular maintenance.

Contact

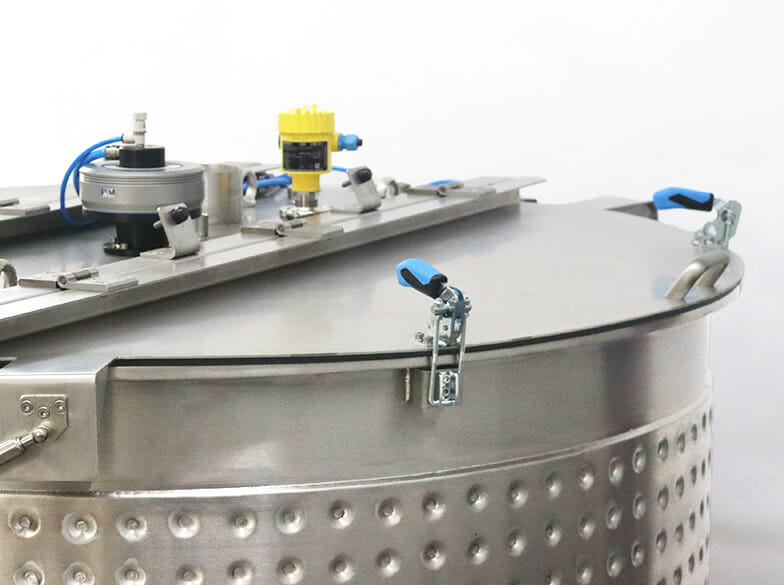

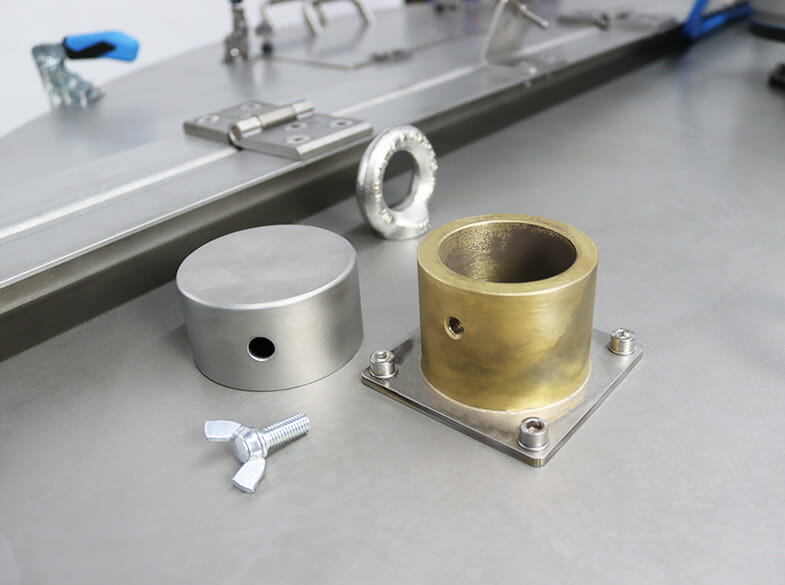

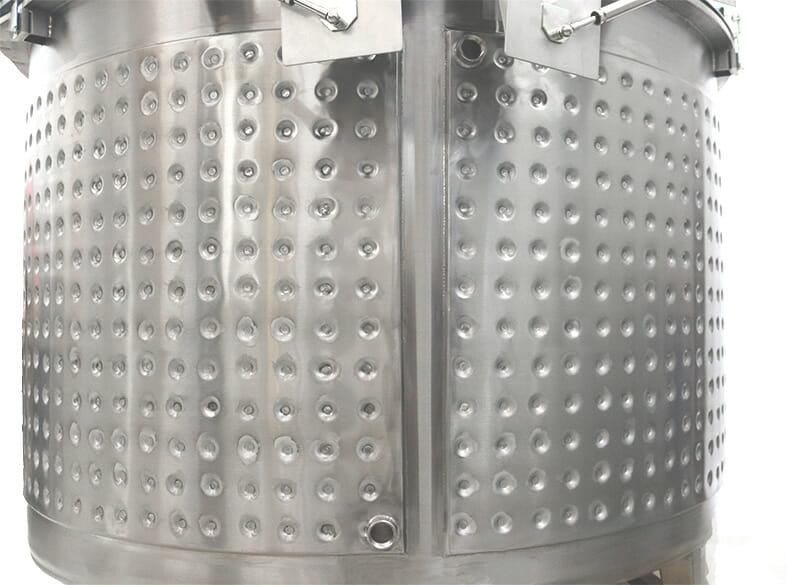

Options & accessories

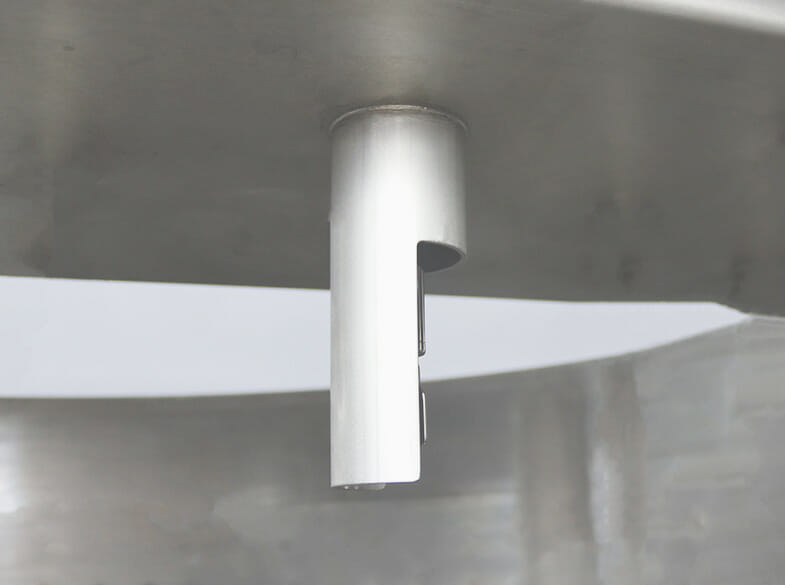

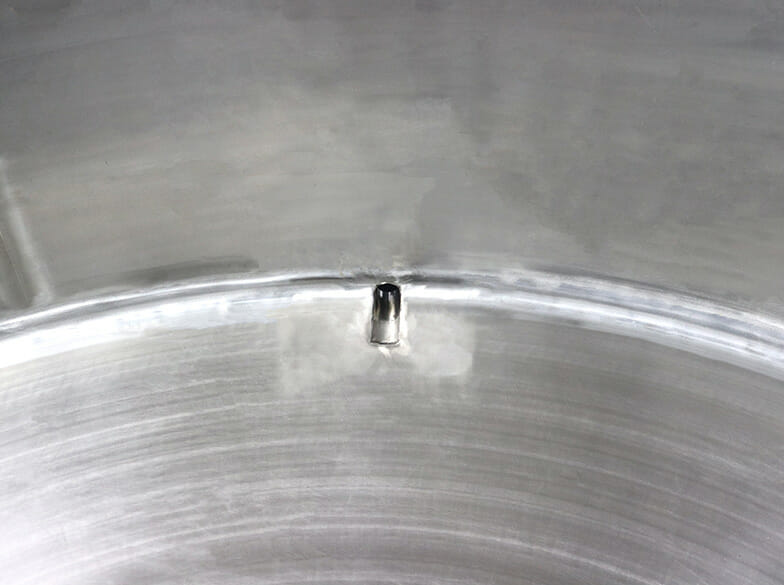

Insertion lance

for filling below level.

Product brochure

Let yourself be inspired by our product brochure.

Overview agitators

From laboratory agitators to large IBC agitators – together we will find your perfect solution:

Please contact us:

If you would like to be advised on our products, our experts will gladly take care of your request: