Stainless steel motors

The stainless steel motor is the all-rounder among motors. Thanks to its diverse properties, it can be used in all conceivable environments. Its advantages at a glance:

- IP68 waterproof and dustproof

- Clean room classification ISO 1 according to DIN 14644

- ATEX certification for ATEX Zone 1

- Acid and chemical resistant

- Sterilisable with hydrogen peroxide

- Efficient and powerful

Technical data and advice

Technical data of our motors is available here. We would gladly advise you on your individual application. For direct contact to our experts please click here.

Advantages

Hygienic

For the food, pharma or cosmetic industry, chemical- and acid-resistant, sterilizable with hydrogen peroxide.

IP68

Waterproof for applications with water and underwater.

ATEX safety

Certified with ATEX certificate II 2 G Ex h IIC T5 Gb X / II 2 D Ex h IIIC T100°C Db X by TÜV Süd.

Clean room class 1

Exemplary applications:

- Food processing machines

- Packaging machines

- Filling plants and lines, breweries

- Backery machines

- Chocolate stirring machines

- Milk collection technology

- Milk processing

- Machines in dusty environments like for example flour dust

- Mills and bulk material transport systems

Options & accessories

Mounting angle

Motor with mounting angle for a quick mounting.

Mounting flange

For an uncomplicated and quick installation.

Bearing flange

Integrated bearing flange for high radial load.

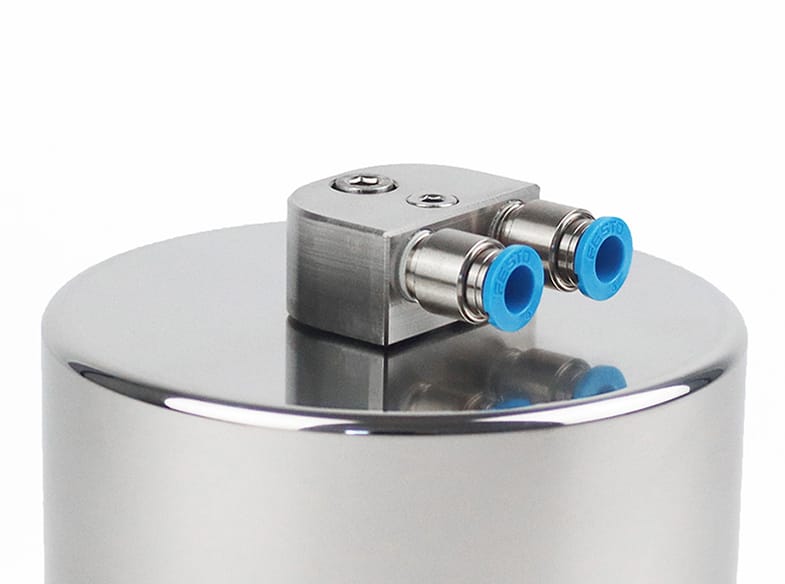

Connection block

Safe connection of supply and exhaust air and practical speed setting via valve in one set.

Orifice

Integrated orifice for speed limitation as overload protection.

Drive shafts

Drive shaft smooth or with feather key, special shaft or stainless steel shaft and IP68 waterproof optional.

Speed sensor

Premounted speed sensor.

Customised solutions

Customised solutions are our speciality.

Not every project, not every problem finds its solution by rummaging in the standard box or by searching the web. With our systematic project management, we also make your wishes a reality – reliably, at the most modern technical level and on schedule.

Customised solutions are our speciality.

Not every project, not every problem finds its solution by rummaging in the standard box or by searching the web. With our systematic project management, we also make your wishes a reality – reliably, at the most modern technical level and on schedule.

Support

Product brochure

Let yourself be inspired by our product brochure.

Overview compressed air motors

Flexible use, robust, efficient and powerful - all our motors at a glance:

Please contact us:

If you would like to be advised on our products, our experts will gladly take care of your request: