Our motors are used all over the world to drive conveyor belts in our food, pharmaceutical, cosmetic and chemical industries. It also unfolds its many advantages when transporting high-explosive devices:

The case study

Our customer, Hammerle Maschinenfabrik AG, offers turnkey, semiautomatic and fully automatic assembly systems (rotary indexing, linear indexing machines and linear transfer systems). His machines impress with their very high process reliability, the highest manufacturing quality and very simple operation.

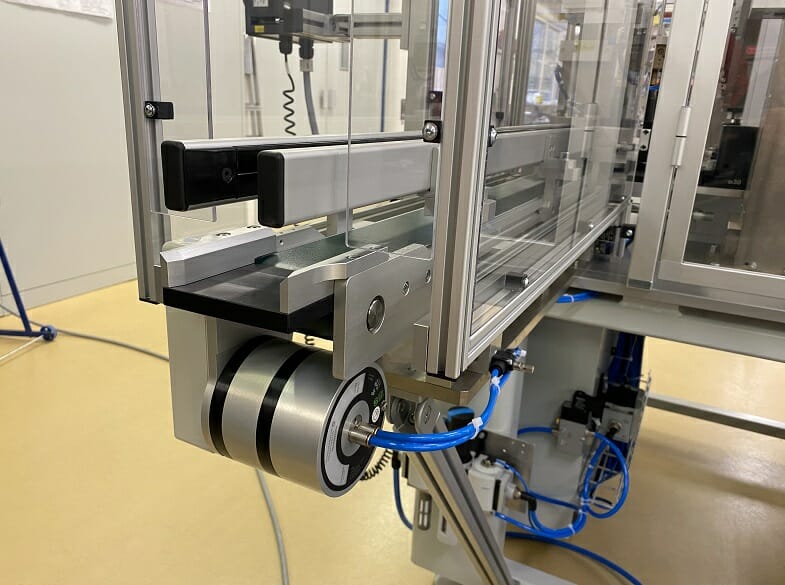

The content of a customer order was the construction of a conveyor belt for a measuring / testing machine for high-explosive devices. One can imagine that smooth transport was of fundamental importance for the success of the project.

For this reason, Hammerle implemented the project with the PTM compressed air motor 450 with ATEX certificate for ATEX Zone 1. We also integrated a 3:1 reduction gear for generating a slow and even movement (including gentle starting). In contrast to the use of electric motors, PTM’s air motors do not generate any inflammable heat. Their robust construction is purely mechanical, without electronics, without sensors. This is what makes their use so safe in all explosive environments.

For more information about our ATEX motors and their application, please click here.

Advice and contact

Do you also have automation projects in extremely explosive environments? Then benefit from our ATEX-certified drives and agitators and our long years of experience in the ATEX area. Contact us under +49 8134 25 797 0 or info@ptm-mechatronics.com.

PTM mechatronics – we generate movement in special environments.

The case study

Our customer, Hammerle Maschinenfabrik AG, offers turnkey, semiautomatic and fully automatic assembly systems (rotary indexing, linear indexing machines and linear transfer systems). His machines impress with their very high process reliability, the highest manufacturing quality and very simple operation.

The content of a customer order was the construction of a conveyor belt for a measuring / testing machine for high-explosive devices. One can imagine that smooth transport was of fundamental importance for the success of the project.

For this reason, Hammerle implemented the project with the PTM compressed air motor 450 with ATEX certificate for ATEX Zone 1. We also integrated a 3:1 reduction gear for generating a slow and even movement (including gentle starting). In contrast to the use of electric motors, PTM’s air motors do not generate any inflammable heat. Their robust construction is purely mechanical, without electronics, without sensors. This is what makes their use so safe in all explosive environments.

For more information about our ATEX motors and their application, please click here.

Advice and contact

Do you also have automation projects in extremely explosive environments? Then benefit from our ATEX-certified drives and agitators and our years of experience in the ATEX area. Contact us under +49 8134 25 797 0 or info@ptm-mechatronics.com.

PTM mechatronics – we generate movement in special environments.