In our plant constuction department, we design and build complete systems for stirring technology. In this case study we developed a 2-component supply system.

What is a 2-component supply system?

A 2-component supply system supplies the downstream process with two components that are mixed with one another shortly before further processing. As soon as these components come into contact with one another, they begin to react with one another and develop a new property. We know the two-component adhesive from daily practice. Two components from two separate tubes are brought together for gluing. Upon contact, they cure in a matter of seconds. 2-component is therefore often a flexible component and a hardener.

The task

Our customer needs the 2-component supply system to manufacture a potting compound. This is used for potting electrical assemblies. The two sensitive components of the potting compound have a viscosity of 3,000 mPas (roughly equivalent to the viscosity of gear oil) and 600 mPas (roughly equivalent to the viscosity of liquid wax).

Both components are sensitive to contact with water or atmospheric oxygen and then harden early. They are delivered in 200l steel drums, have to be stirred for processing and then pumped into the potting process.

Our solution

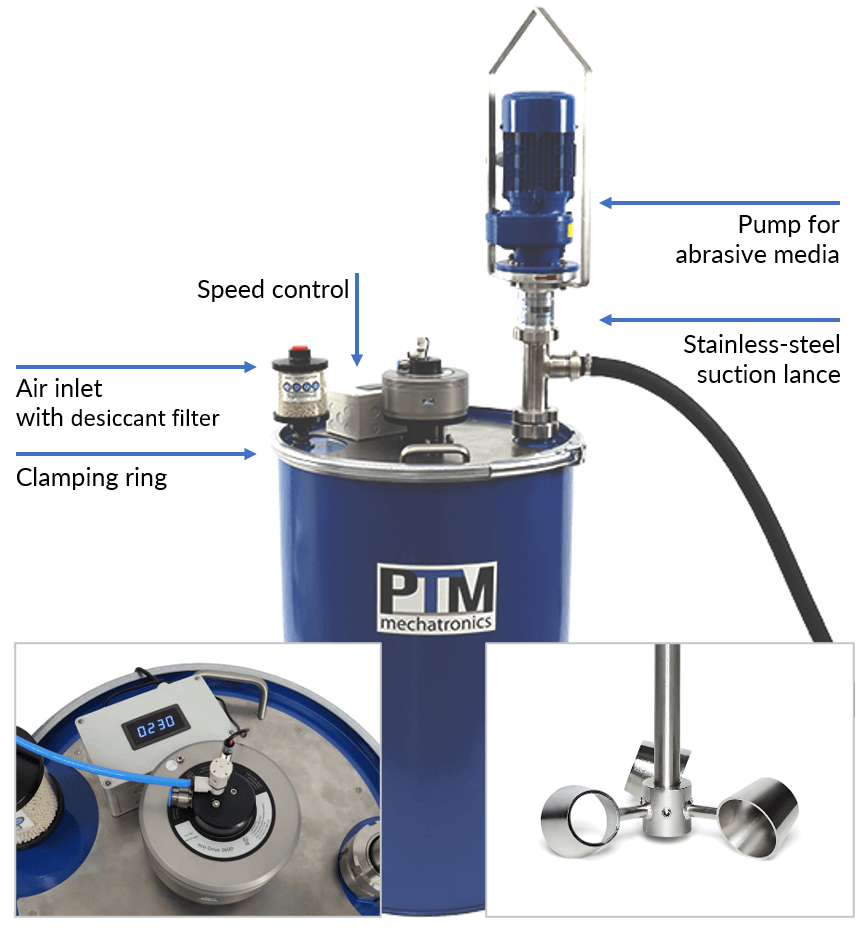

A special interchangeable lid made of stainless steel was designed for the 200l drums of both components respectively. Due to the different viscosities, the lid for the 600mPas component was equipped with a 16Nm drive and the hollow-body impeller eco-Cup. The 3,000mPas component received the more powerful 32Nm drive with two eco-Cups. Otherwise, both lids were identically equipped as follows:

- Clamping ring solution for easy changing of the container

- Digital speed display (as the stirring process cannot be seen in the completely closed container)

- Special pump for abrasive media (due to the quartz content in the components) with an output of 3 l / min.

- Stainless-steel suction lance

- Air inlet with desiccant filter with humidity indicator (to absorb the ambient humidity)

In our plant construction, we also implement your ideas for everything to do with drive and stirring technology. Just contact us.

PTM mechatronics – we generate movement in special environments.

Please contact us:

If you would like to be advised on our products, our experts will gladly take care of your request: