Tripod agitators for IBC tanks

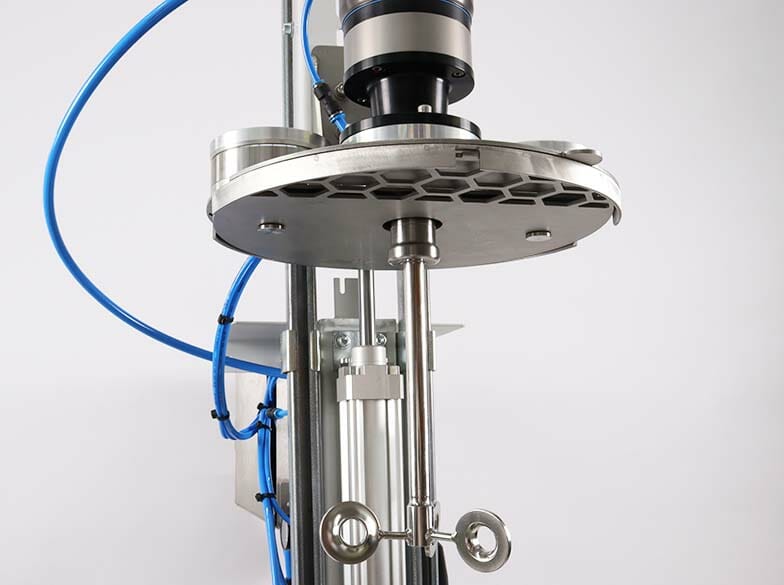

With our tripod agitators for IBC tanks, you can easily, efficiently and safely handle IBC agitators that are heavy due to their size. Thanks to the automatic lifting mechanism, all work on the agitator can be carried out by just one person.

You also receive maximum occupational safety. When implementing the safety standards, we adhere to the DGUV guidelines.

Features:

- ATEX certified for ATEX Zone 1 or 0/1

- Lifting height 1,200mm

- Ideally suited for loading with a forklift

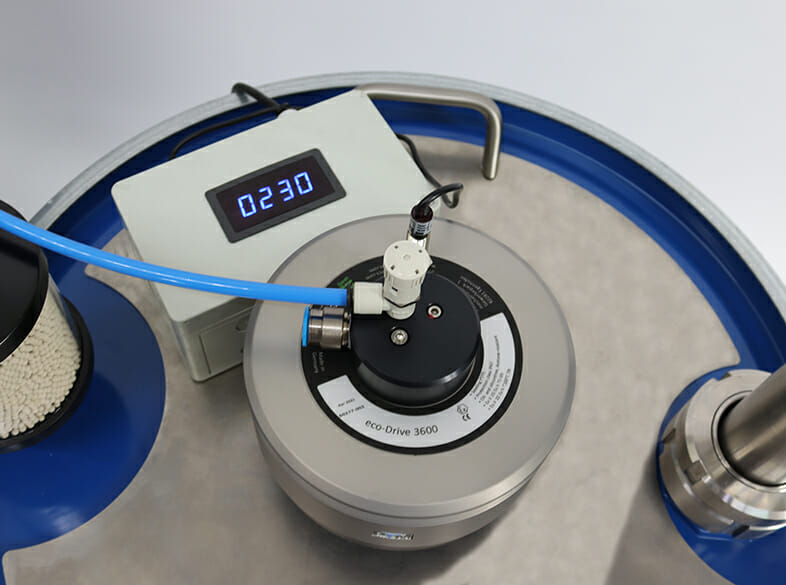

- Restart protection eco-Start

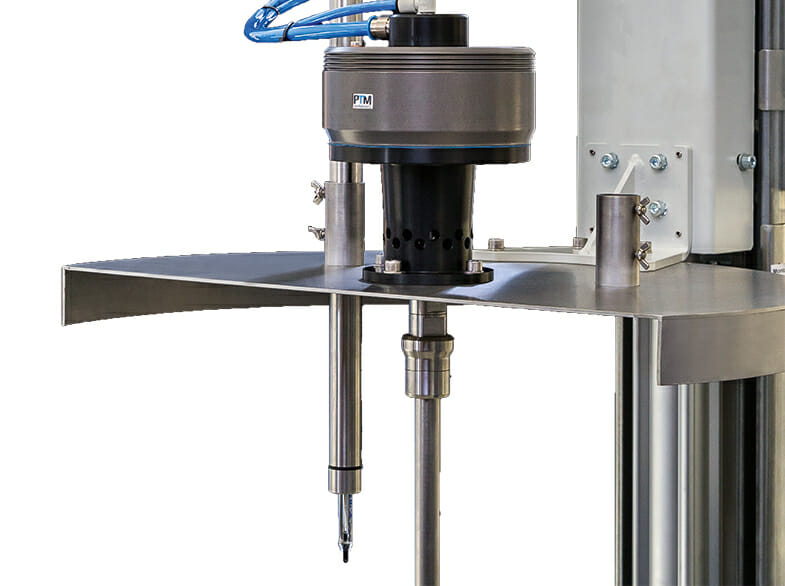

Our tripod agitators are available with either a pneumatic or electric drive. The right choice depends on your working environment, your stirring task and the medium to be stirred.

The eco-Start start-up system is integrated as standard: a sensor in the lid only starts the agitator when the lid comes into contact with the opening of the container. This prevents reaching into moving parts.

Contact

We would be happy to advise you on your individual requirements. The direct contact for a non-binding consultation can be found here. Technical details can be found in our download area here.

Tripod agitators for IBC tanks

With our tripod agitators for IBC tanks, you can easily, efficiently and safely handle IBC agitators that are heavy due to their size. Thanks to the automatic lifting mechanism, all work on the agitator can be carried out by just one person.

You also receive maximum occupational safety. When implementing the safety standards, we adhere to the DGUV guidelines.

Features:

- ATEX zertifiziert für ATEX Zone 1 bzw. 0/1

- Fasserkennung beim Absenken des Rührwerks

- Sicherheitsgitter an der Entnahmeklappe

- Rührwerksabschaltung beim Anheben des Deckels

- Wandbefestigung möglich

Our tripod agitators are available with either a pneumatic or electric drive. The right choice depends on your working environment, your stirring task and the medium to be stirred.

The eco-Start start-up system is integrated as standard: a sensor in the lid only starts the agitator when the lid comes into contact with the opening of the container. This prevents reaching into moving parts.

Contact

We would be happy to advise you on your individual requirements. The direct contact for a non-binding consultation can be found here. Technical details can be found in our download area here.

Options & accessories

Stirring containers

We will also supply you with the appropriate stirring container.

Downloads

Advantages of tripod agitators

Flexibility

We would be happy to adapt our tripod agitators to your individual requirements.

Occupational safety

Our tripod agitators meet all occupational safety requirements.

Speed

Due to the uncomplicated handling, you can quickly switch between different containers.

Cleanliness

The vertical movement of the tripod agitators guarantees clean handling.

Overview Stirring technology

From laboratory agitators to large IBC containers – find your perfect solution:

Product brochure

Let yourself be inspired by our product brochure.

Please contact us:

If you would like to be advised on our products, our experts will gladly take care of your request: