When developing our products, occupational safety is always our top priority. Where can dangerous situations arise and where do machines pose a safety risk? The DGUV’s “Safety Requirements for Tripod and Hanging Agitators” serve as a guide in the area of stirring technology.

The DGUV states: “There is currently no European harmonized work equipment-specific standard for tripod and hanging agitators. However, since agitators with very different levels of safety are offered on the market, safety concepts were developed in an exchange of experiences between manufacturers, operators, professional associations and associations that do not provide any incentives to bypass protective devices and ensure safe machines using state-of-the-art technology.” (Source: Safety requirements for tripod and hanging agitators, DGUV, https://publikationen.dguv.de/widgets/pdf/download/article/3515)

Here are the possible dangerous situations according to the DGUV and our solution:

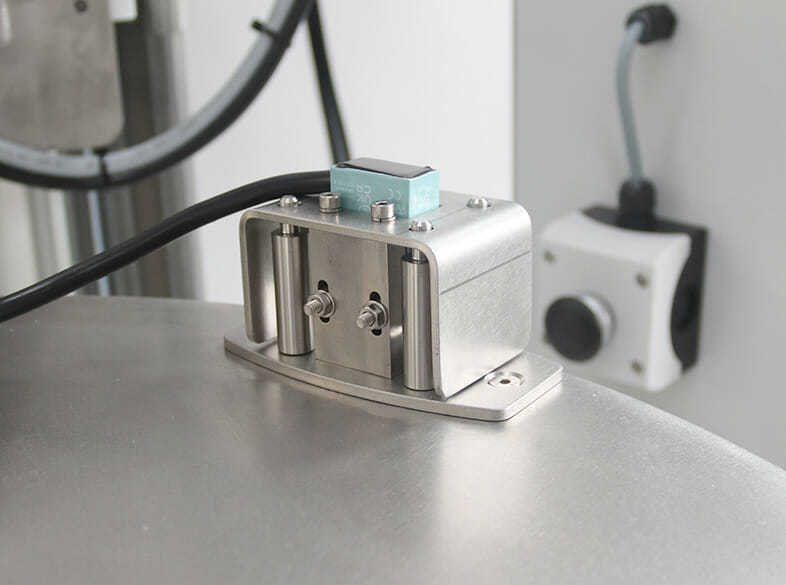

1. Protective devices against hazards caused by the mixing element / protective devices against hazards caused by rotating agitator shafts:

Unsere Stativrührwerke sind standardmäßig mit einem Deckel kombiniert mit unserem Sicherheitssystem eco-Start ausgestattet. Ein Sensor stellt sicher, dass das Rührwerk erst startet, wenn der Deckel des Rührwerks auf dem Rührbehälter aufsitzt. Damit verhindern wir effektiv das Greifen in bewegliche Teile.

2. Container lid with addition opening

Our lids can be equipped with an addition flap. In this case we secure the opening with a safety grid.

3. Minimum control requirements for existing machines

Our tripod agitators are equipped with a two-hand control that does not offer any manipulation options. The control also has an easily accessible emergency stop.

Sometimes the implementation of the above conditions leads to conflicts with the stirring task. For example, the container should remain open or the addition flap should not be closed by a safety grid. Here we can install a secure access area with protective fences and sensors to still make the agitator 100% safe.

Advice and contact:

We would be happy to advise you without obligation on the safety requirements for your stirring system. From laboratory stirrers to large IBCs: we design your individual stirring application with the best possible occupational safety.

Please contact us:

If you would like to be advised on our products, our experts will gladly take care of your request: