The first step is to prevent dirt deposits from forming in the first place. You can achieve this by avoiding grooves, edges and undercuts on devices and machines in your production as far as possible. In addition, the selection of suitable materials for the devices and machines used can help make surfaces less susceptible to contamination. For this purpose, surfaces can also be refined with special surface treatments.

Nevertheless, of course, not all deposits can be avoided. Then all devices and machines in a hygienic production should be resistant to effective, but often aggressive cleaning agents for easy cleaning.

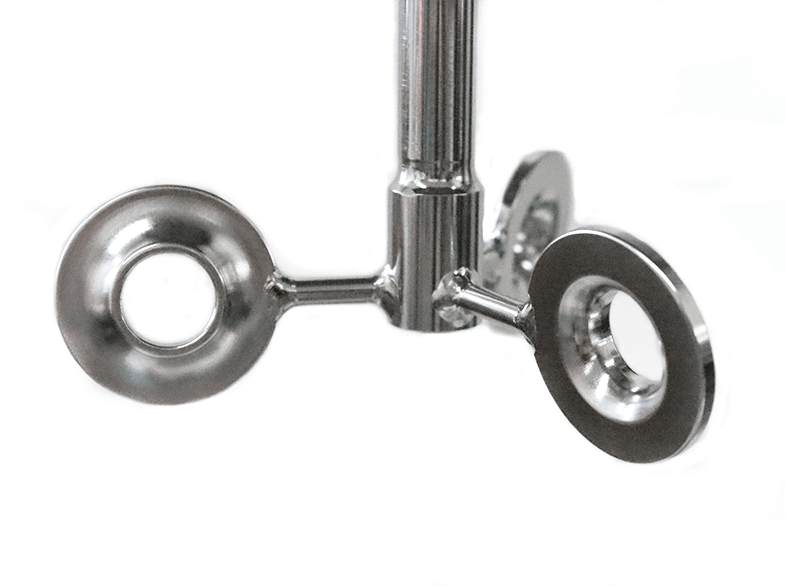

Our impellers and agitator shafts offer you the following advantages with regard to the points mentioned:

Our impellers and agitator shafts are welded together in order to avoid grooves. The weld seam is as smooth and even as possible (soft-edge design).

Our impellers and agitator shafts are made of high quality V4A stainless steel 1.4404. The robust material can be treated with hydrogen peroxide and other aggressive cleaning agents without being damaged.

Our stirring elements and shafts are then electropolished. This greatly reduces the surface roughness. As a result, the surface is even less susceptible to the build-up of germs.

Please contact us:

If you would like to be advised on our products, our experts will gladly take care of your request: