Flexibility between 15 and 1,100 liters

Lienig uses different stainless-steel containers for processing their fresh fruit, which can vary from small containers of 15 to 60 litres to large IBC and stainless-steel containers with a capacity of 600 up to 1,100 litres. And this was exactly where the challenge was now. Our customer wanted a single, very flexible agitator for all these container sizes, with their varying openings from Ø15 to 500mm, in order not to have to have a separate agitator ready for each container size.

The solution of our experts

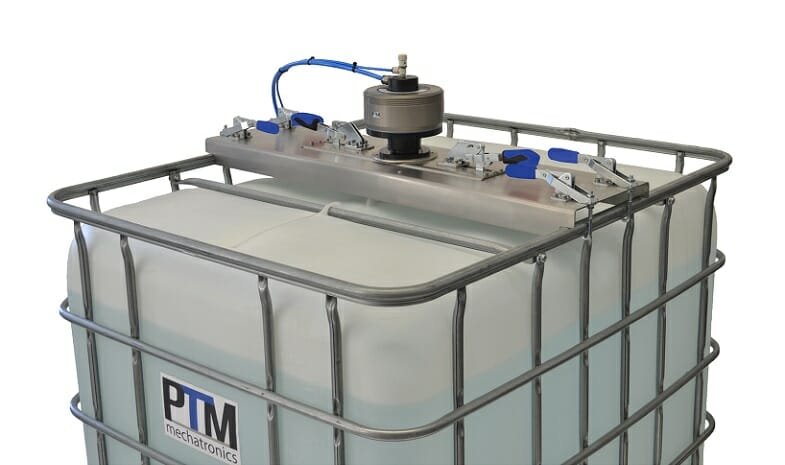

Our development department constructed a complete system consisting of an agitator and a flexible, plug-in traverse:

In order to mix the highly viscous fruit pulps reliably, the choice fell on our most powerful agitator drive with protection class IP67 and a torque of 32Nm. The agitator shaft and impeller were designed in two different sizes and, thanks to the standard thread on the drive, can be easily exchanged when changing the container.

A small traverse made of high-quality stainless steel fixes the agitator both to small containers and to the stainless-steel containers with DN400 openings. To fix the agitator on IBC containers, the small traverse is simply plugged onto a large traverse – converted within a few seconds. In this way, Lienig now serves all container sizes from 15 to 1,000 litres with just a single agitator.

Feedback from our customer

Richard Albrecht, Deputy Production Manager of Lienig: “While looking for ways to make our processes more efficient, we came across the compressed air-powered agitators from PTM mechatronics. Flexibility and good handling are of great importance to us. Thanks to the professional technical support of PTM mechatronics we got a suitable solution that meets our needs.”

We develop your agitator and equipment tailored to your requirements. Our experts will be happy to advise you: +1 (850) 462-2730 or info@ptm-mechatronics.com.

You can find more information about our agitator technology on our product page.

PTM mechatronics – we generate movement in special environments.