Types of flow during the stirring process

In stirring technology, there are generally two types of flow that are decisive for the stirring process and must be taken into account accordingly: laminar and turbulent.

What are laminar and what are turbulent flows?

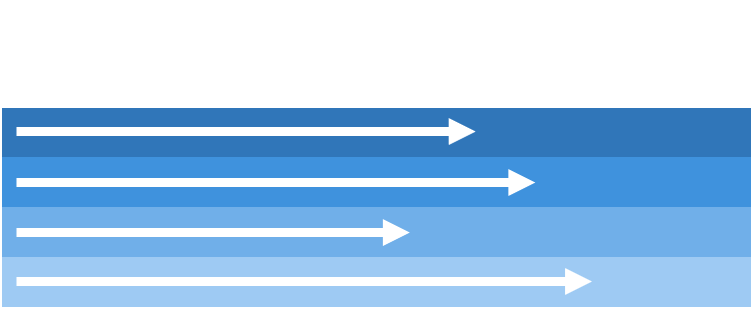

With laminar flows, the medium flows in layers that do not mix with one another. The layers slide past each other. This is especially the case at low flow velocities. Examples of laminar flows are the flow of blood in the human body or the flow of groundwater.

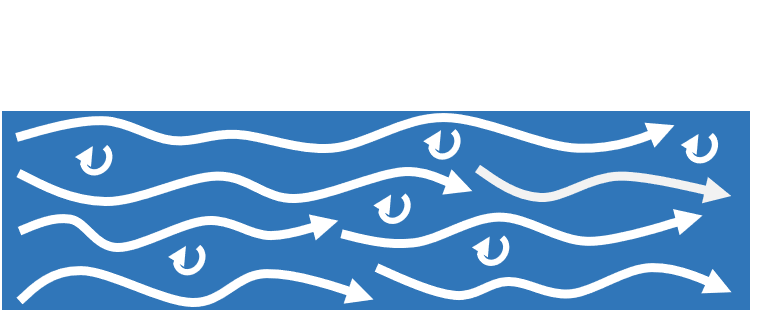

If the flow speed is increased, irregular turbulence occurs in all three dimensions. The layer structure dissolves. The exchange of particles is increasingly chaotic and increases with increasing speed. This effect is often supported by built-in components in the stirred tank, so-called baffles. Examples of a turbulent flow are the poured milk in coffee or eddies in a river.

Laminar or turbulent stirring?

From the previous explanations it can be deduced that the mixing or heat distribution within a mixed material is faster and more effective with turbulent flows than with laminar flows. This is always useful when the mix reacts insensitively to the flow and possible shear forces. The laminar flow acts more gently on the mix. Sensitive substances should therefore be stirred in a laminar manner.

Laminar flow

Turbulent flow

PTM Wiki

There is even more worth knowing in our PTM Wiki.

Please contact us:

If you would like to be advised on our products, our experts will gladly take care of your request: