High degree of indiviualisation and a tight time schedule – these were the challenges, our costumer, a well-known paint factory, confronted us with.

In his production, our customer uses special parts in his everyday business. These parts get dirty during operation and need to be cleaned regularly. Instead of cleaning every part separately, this work undertakes an industrial washing system. So far, all parts have been fixed to a bar and cleaned by a cleaning noozle, both immovably fixed to the washing cabin. The parts then have had to be turned by hand. Afterwards, the washing process had been repeated. This cumbersome process now had to be facilitated and automated.

Idea was to let the parts rotate on a rotation axis so that the fixed cleaning nozzle could reach every side of the parts. The requirements of ATEX zone 0, which the customer required inside the cabin, had to be fulfilled. As experienced manufacturer of drive and stirring technology with deep ATEX knowledge and an in-house development department with experienced engineers specialised in special solutions, PTM mechatronics was the perfect partner for our customer to conduct this project.

ATEX rotation axis as industrial washing system.

For realisation, the washing system was delivered to us. As the machine had to be sent back immediatly, our engineers generated a CAD model of the machine on short notice.

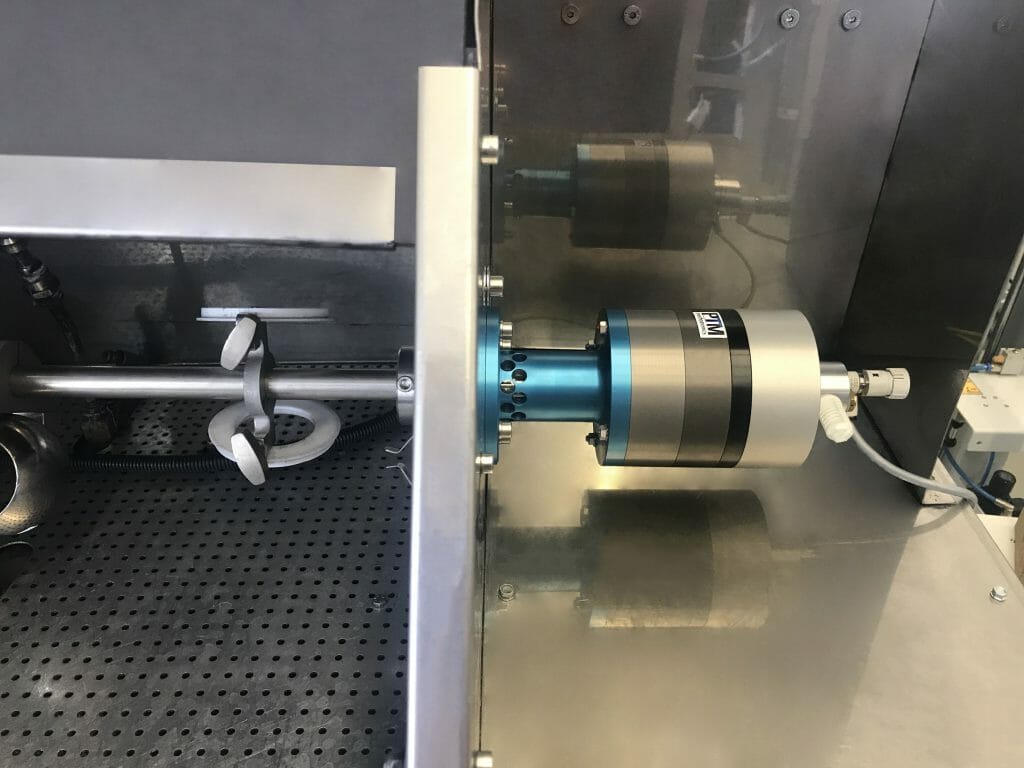

All parts needed for realisation were now created and produced by means of the CAD model. Our ATEX certified and energy-efficient radial piston motor formed the basis of the construction and was equipped with a rotation axis. Our special PTM zone separation flange provided the secure separation between ATEX zone 1 outside and ATEX zone 0 inside the cabin. Additionally, we equipped the construction with a special sealing concept to avoid leakage of gas and solvents. Finally, we attached mountings to the axis especially customised to the customer’s parts.

For assembling and final tests, the machine was delivered to us once more, which bound us to a tight time schedule again. After only two days, the washing system could be accepted by our customer and delivered back.

Here you can see our ATEX rotation axis during test operation:

You are currently seeing a placeholder content of Youtube. To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

The possible applications of our ATEX rotation axis are diverse, from washing systems of all kinds to cleaning brushes of painting robots and many more. We gladly adapt our rotation axis for ATEX zone 0/1 to your individual requirements. Our experts are looking forward to advising you: +1 (850) 462-2730 or info@ptm-mechatronics.com.

PTM mechatronics – we generate movement in special environments.