PTM compressed air motors – versatile and individual

Our PTM compressed air motor is an extremely flexible drive with numerous kinds of application. It is robust, incomparably powerful and energy-saving at the same time. In times of energy revolution and the urge to steadily increase efficiency, our motors are used in more and more applications in different industries. They are the heart of our stirring technology eco-Series.

Together with our in-house development department its applications are so diversified that it is difficult sometimes to embrace all the possibilities at a glance. This is why we introduce some of our development projects under the title “PTM compressed air motors – versatile and individual”. In all these projects our engineers have developed new ideas based on our radial piston motor.

The task

Our customer, the TECLAC Werner GmbH with its business seat in Fulda, Germany, is expert for the surface treatment of plastic components of the automotive interior and exterior as contract manufacturer. Additionally, their offer also includes ready-to-use components.

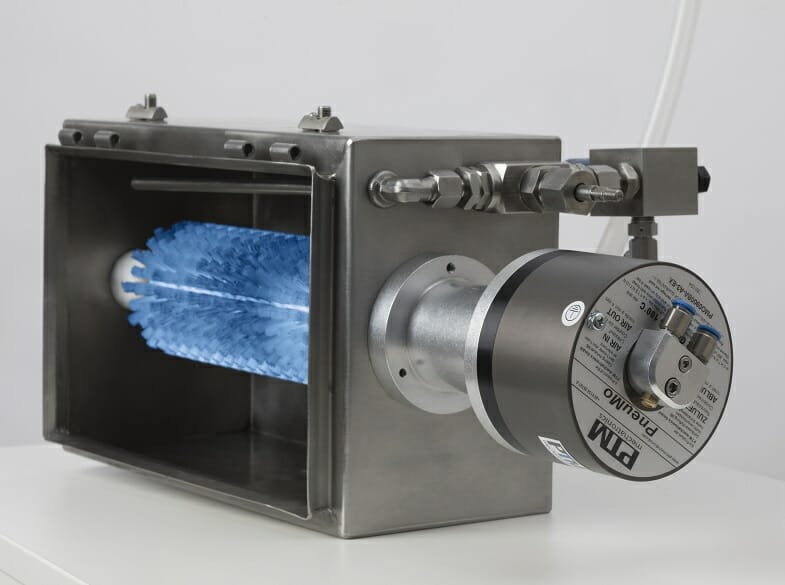

TECLAC is specialist for the varnishing of plastic surfaces of outstanding quality. This high standard sets high requirements for all production devices and systems accompanying the product through its production process. To apply the varnish, TECLAC works with paint robots and spray guns. Spray guns are precision tools which need to be cleaned regularly, for example when changing colours. Manual cleaning is neither an efficient nor a clean solution. Here, the cleaning brush with our PTM compressed air motor goes into action.

PTM compressed air motor as drive for cleaning brush for paint robots

Engineering with inventive spirit

At first our customer only searched for an adequate drive for his cleaning brushes. This one he found in our PTM motor which is not only energy-efficient and powerful but also waterproof according to protection class IP68. TECLAC sent his cleaning unit to us. To just integrate the motor was not possible. A custom-made solution should solve the problem.

First step was to transfer the construction of the cleaning brush into a CAD model. Afterwards, the PTM motor was integrated into the model as efficiently and solidly as possible. After finishing the unit technically, the motor with all its components were fitted into the cleaning brush by means of the CAD model.

Our customer tested the cleaning brush in real operation. Today, already ten cleaning brushes are in daily operation.

Methodical project management

Special solutions are our speciality. We are specialised in the fields of pneumatic and electronic stirring and drive technology. We work with a methodical project management which guides all departments that work on our projects. Our departments work hand in hand with flat hierarchies. Open communication and accurate documentation are the basis of our project management. This also applies to the interaction with our customers, which we always keep informed about the intermediate stages. Our products are accompanied by detailed documentation and our professional customer service over their entire service life.

Special solutions from the PTM manufactory

PTM has an in-house development department. Our engineers are specialised in constructing special solutions. Our guiding principle, with which we always start our projects, is: Nothing is impossible. This is why we approach every task openly and with our curious inventive spirit. Modern software and work equipment guarantee the best possible solution.

All products are manufactured in our own machine park and afterwards assembled in our assembly department. This is how we can guarantee the high quality of our products.

In case of any questions about our offer or any requests, please contact our customer service: +1 (850) 462-2730 or info@ptm-mechatronics.com.

PTM mechatronics – we generate movement in special environments.