Chocolate challenge

In this project, maximum flexibility on a large scale was required. Of course, we gladly accepted the challenge, because the medium to be stirred was very tempting: delicious, melt-in-the-mouth premium chocolate in a wide variety. Who could say no to that…

In order to meet the high quality requirements for creaminess and tenderness, the stirring process in chocolate production is essential. And poses some challenges for the construction of our tripod agitator with a total height of 3.6 meters:

Chocolate challenge

In this project, maximum flexibility on a large scale was required. Of course, we gladly accepted the challenge, because the medium to be stirred was very tempting: delicious, melt-in-the-mouth premium chocolate in a wide variety. Who could say no to that…

Passion Chocolat Suisse – that has been Maestrani since the brand was created in 1852 by Aquilino Maestrani. Since then, the company has stood for high-quality chocolate and chocolate creations in countless flavors and forms of presentation.

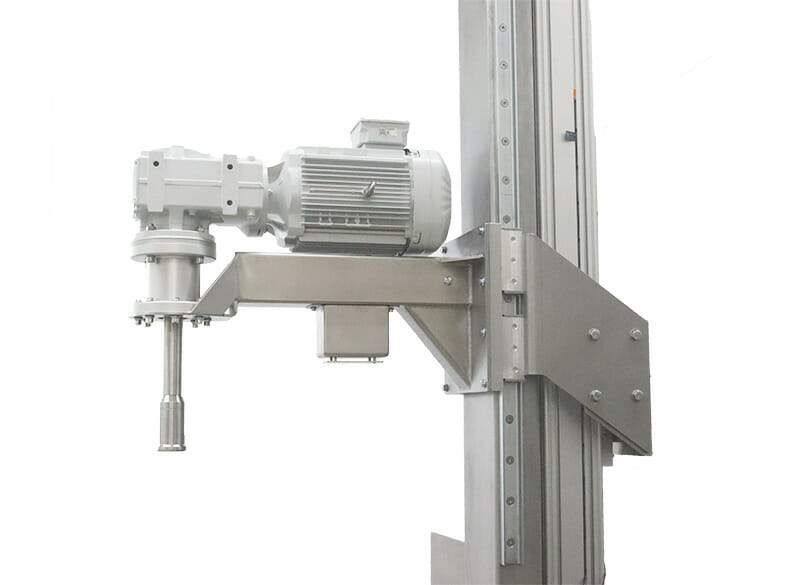

In order to meet the high quality requirements for creaminess and tenderness, the stirring process in chocolate production is essential. And poses some challenges for the construction of our tripod agitator with a total height of 3.6 meters:

Various container sizes and heights

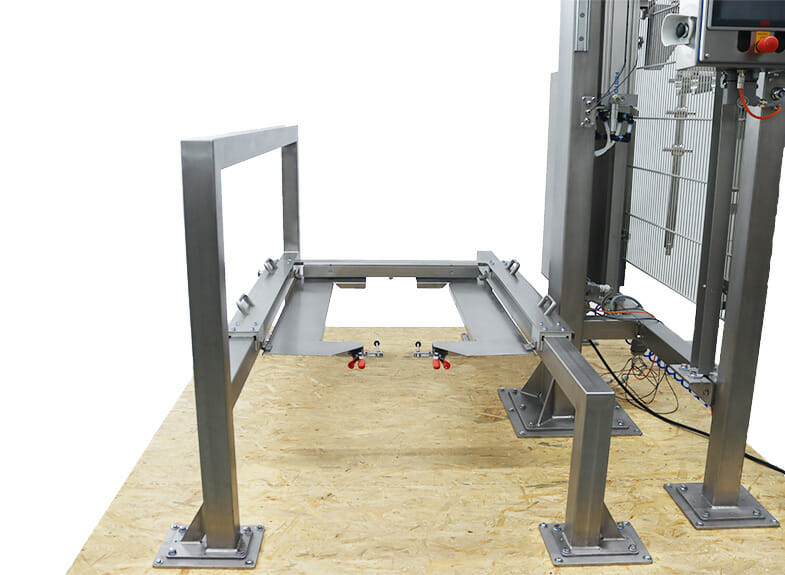

Over the years, different containers have become established in Maestrani’s production: large, small, sometimes with rollers, sometimes without, sometimes completely open, sometimes closed with a manhole opening. It goes without saying that this range of containers could not be reduced to one single standard container for the stirring process. The agitator therefore had to be able to adapt to the containers.

Our solution:

In the first step, all containers were measured. We were then able to divide these into three categories. For each category, we defined the necessary dimensions for the space in front of the tripod agitator. From the data we constructed a base frame with devices that could be folded in and out. These container holders ensure that the respective container is stable. Sensors check that the container and stand fit together and automatically retrieve the appropriate data from the digital, touch-based control eco-Control, which releases the stirring process.

Different viscosities, different ingredients

Chocolate is not just chocolate. Dark, whole milk, with coconut, with hazelnuts…a wide range requires maximum flexibility in the mixing process. Highly viscous masses must be stirred efficiently and homogeneously, while ingredients must be introduced gently.

Our solution:

We solved this with a powerful agitator that can stir up highly viscous media within a very short time. In order to protect the contents nevertheless, we combined our gentle impeller eco-Cup with its low shear forces and gentle mixing.

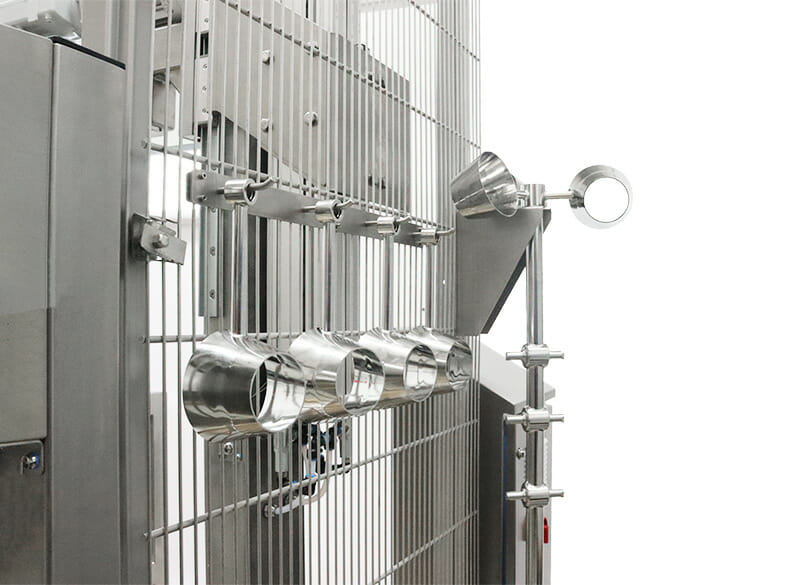

Different filling levels

Of course, the different container sizes also resulted in different filling levels.

Our solution:

In order to do justice to this, the size of the impeller also had to be adjusted. For this we developed special attachments at different heights and in different numbers on the agitator shaft. The cups of the impeller can now be attached and removed quickly and easily here. For the optimal organization of the process, the tripod agitator has a practical mounting within easy reach for the cups that are not needed at the moment.

Absolute control of the stirring processes

The different mixing containers, mixtures and ingredients to be mixed result in a wide range of requirements for the mixing process. Manual settings take too long here, are too imprecise and too complicated. And here anyway not useful due to the good reproducibility.

Our solution:

Our control eco-Control provides the complete management of the stirring processes, here called recipes. Maestrani can now save countless recipes in a collection and call them up at the touch of a button. Parameters such as speed and stirring time can be freely determined. In this way, any number of different stirring sequences with different speeds can be run one after the other. Mix, stir new ingredients in, homogenize – everything is possible within one recipe.

Advice & contact

We build customer-specific systems for you: from the agitator tank to the agitator itself to the automated control. Our experts will be pleased to advise you.

PTM mechatronics – we generate movement in special environments.

Please contact us:

If you would like to be advised on our products, our experts will gladly take care of your request: